Semilab offers versatile solutions for semiconductor industry needs, spanning

material assessment to back-end processing. Our equipment enables sensitive

Silicon testing, precise epi resistivity measurement, and optimization of dielectric properties. We cover ion implant monitoring, defect detection, and backend

characterization with non-destructive methods, offered in flexible automation

levels.

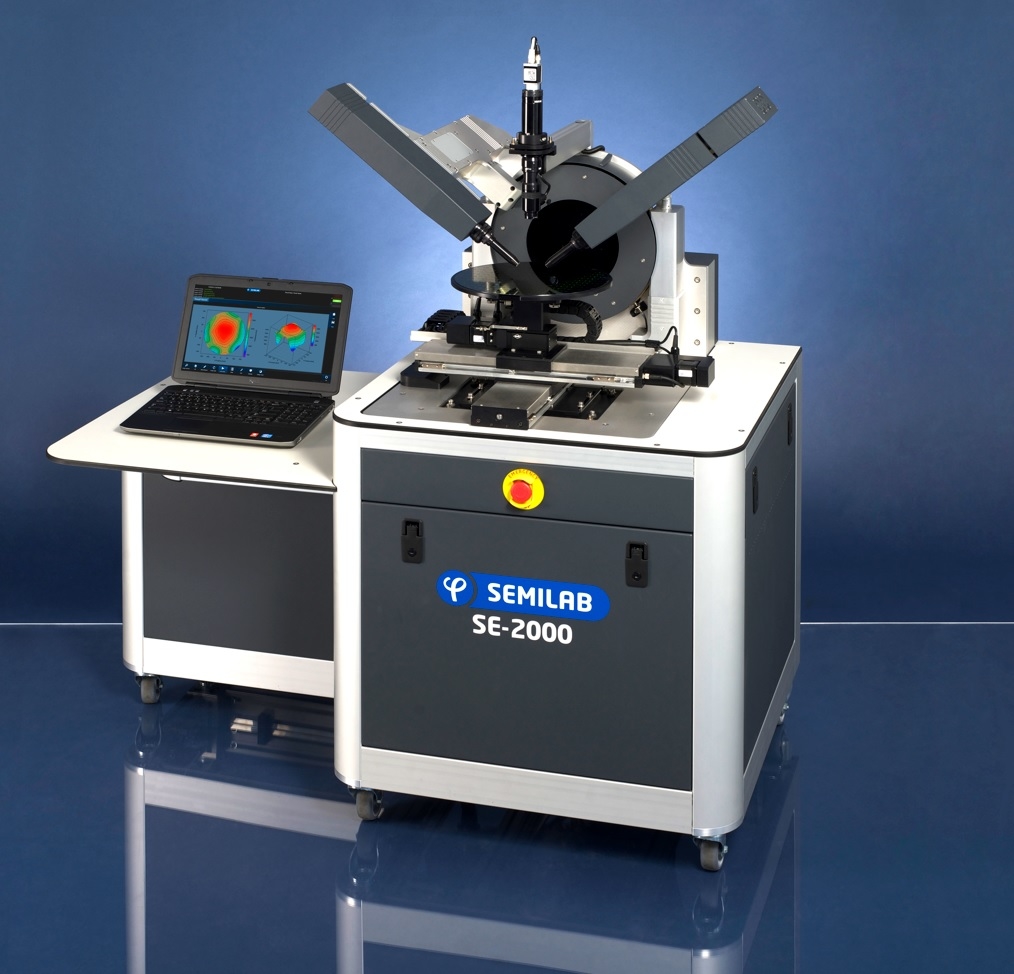

Semilab offers advanced substrate inspection equipment for the semiconductor

industry. From initial assessment to final processing, our solutions provide high

sensitivity for contaminant detection, precise epi resistivity measurement, and

optimization of dielectric properties.

Covering ion implant monitoring, defect detection, and backend characterization, our non-destructive methods come in flexible automation levels.

Semilab boasts an extensive technology portfolio designed for monitoring flat

panel display production.

Our dedicated product line, the Flat Panel Tester tool, excels in assessing optical

and electrical properties of layers during manufacturing on large area substrates within the fab setting.

We complement this with lab tools for R&D and offline quality control purposes.

Leveraging strong scientific expertise and collaborative history, Semilab crafts

tailored R&D solutions for semiconductor, photovoltaic, and flat panel industries,

thin film research, and materials science.

Specializing in thin film and surface characterization, our versatile systems

address a wide array of needs. We actively engage in joint scientific work,

showcasing results in conferences and quality publications to ensure

optimal solutions through collaboration.

Semilab offers complete solutions for controlling crystalline silicon solar cell

manufacturing. From feedstock testing with handheld probes to advanced wafer qualification using in-line imaging, our tools cover property assessment, defect

detection, and quality control.

Versatile lab tools support R&D and quality assurance.