Excimer Laser Annealing (ELA) plays a crucial role in the manufacturing of Low-Temperature Poly-Silicon (LTPS) layers, serving as a key process parameter. ELA influences several critical parameters of the layer and, consequently, the device itself, including crystallinity and mobility, among others. Semilab has developed a combination of metrology techniques that can readily determine the Optimal Energy Density (OED). This unique combination allows for distinguishing between the properties of two LTPS samples that have undergone annealing with very similar parameters. With this capability, fine-tuning the ELA process becomes a quick and straightforward task, eliminating the need for macro inspection and human decision-making.

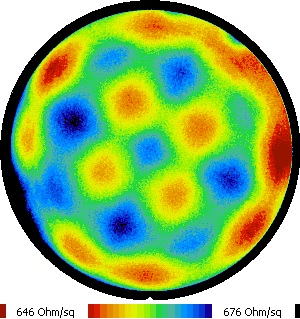

Additionally, our contact 6pp method can be used to determine sheet resistance