Features and System specifications:

Optical thickness and refractive index of multilayered oxide and semiconductor structures can be determined by spectroscopic ellipsometery at different process steps. The quality of the ELA process can also be monitored by measuring crystallinity, u-PCR and line mura density. Contact angle, stress and resistivity measurements are also available.

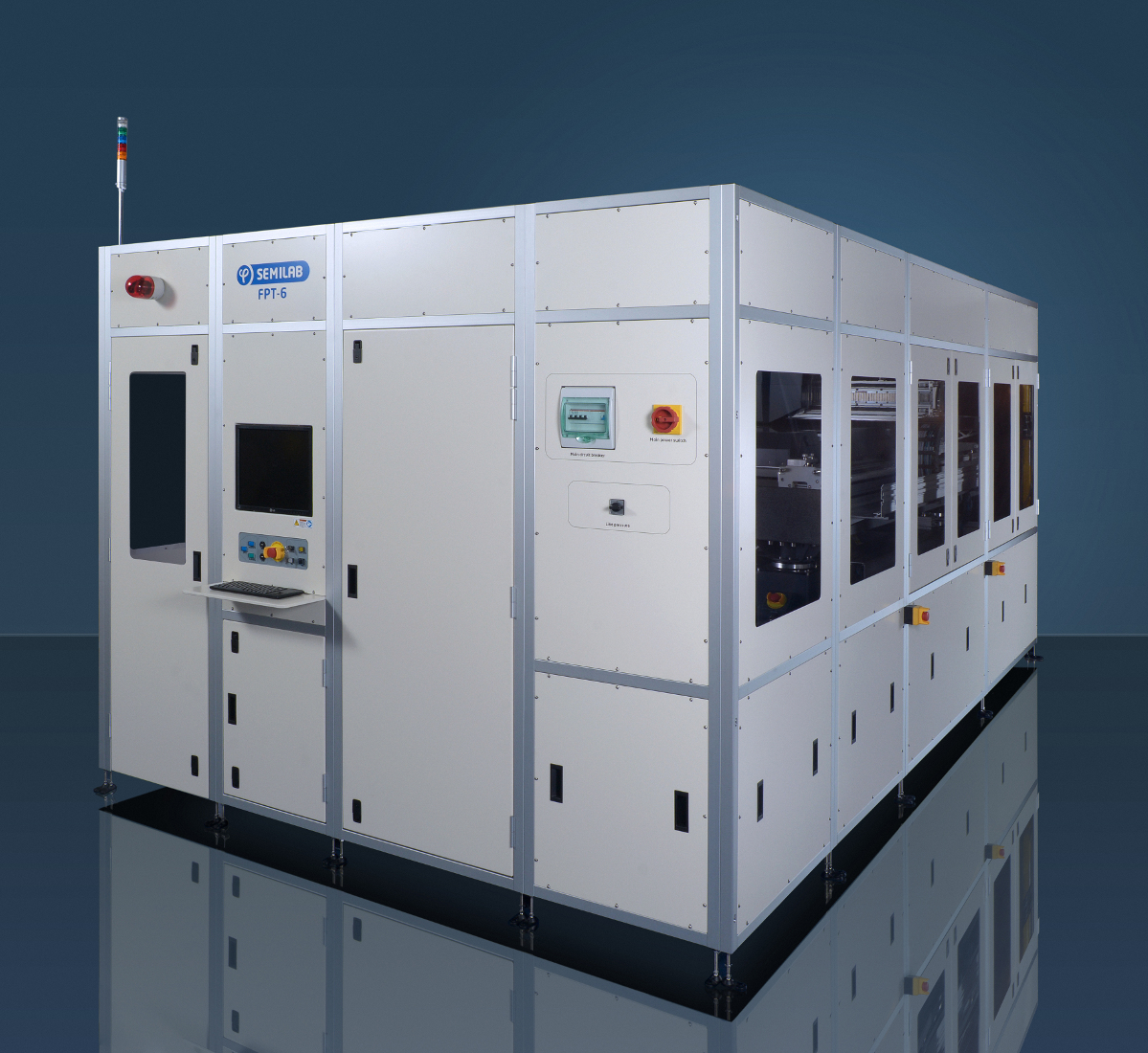

The hardware and software are fully controlled by SEMILAB from the design to the integrated software communication with the fab.

CHIP QUALITY (LINE MURA AND µ-PCR)

Chip quality measurement method is a combination of the electrical Microwave Photoconductive Response (μ-PCR) and the optical LineMura metrologies, where the result is a function of measured values which describes the quality of the thin film.

The „Chip quality” - chip (or device) is a selected area unit on the production plate - is a weighted, normalized sum of the μ-PCR and LineMura parameters.

Normalization for μ-PCR Amplitude, Lifetime 1-2 and LineMura Brightness:

•Normalized value = Raw value/Normalization factor

Normalization for LineMura relative deviation values:

•Normalized value = Normalization factor/Raw value

Line Mura is an optical method for characterization of an LTPS layer - low temperature poly-silicon thin film - by identifying the Excimer Laser Annealing (ELA) process caused defects and nonuniformities (mura) and the Optimal Energy Density (OED) of the laser. The metrology consists of a flat angle illumination and flat angle camera system.